Difference between revisions of "Metal DC Geared Motor w/Encoder CQGB37Y001"

(→SPECIFICATION) |

(Created page with " right |thumb|400px|6V/12V Metal DC Geared Motor w/Encoder-CQRDJ-GL =='''INTRODUCTION'''== This gearmotor is a powerful '''12V/6V''' br...") |

||

| (64 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | [[File: | + | [[File:DC Geared Motor CQRobot-1.jpg| right |thumb|400px|6V/12V Metal DC Geared Motor w/Encoder-CQRDJ-GL]] |

=='''INTRODUCTION'''== | =='''INTRODUCTION'''== | ||

| − | + | This gearmotor is a powerful '''12V/6V''' brushed DC motor with a '''6.25:1/10:1/18.8:1/30:1/43.8:1/56.3:1/70:1/90:1/131.3:1/168.8:1/210:1/270:1/393.8:1/450:1/506:1/630:1/810:1''' metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 5760 (90:1) counts per revolution of the gearboxot is output shaft. These units have a 16 mm-long, 6 mm-diameter D-shaped output shaft. | |

| − | + | When the working voltage of the DC gear motor is '''12V''', the motor rotation speed is '''11,000''' rpm before the motor is decelerated. When the working voltage of the DC gear motor is '''6V''', the motor rotation speed is '''5500''' rpm before the motor is decelerated. | |

| − | + | {|- | |

| − | + | |[[File:CQGB37Y001-771.jpg |left|770px]] | |

| − | + | |} | |

| − | + | '''Note''' | |

| − | + | Stalling is likely to damage the gearmotor. Stall parameters come from a theoretical extrapolation of performance at loads far from stall. As the motor heats up, as happens as it approaches an actual stall, the stall torque and current decrease. | |

| − | + | Do not screw too far into the mounting holes as the screws can hit the gears. CQRobot Manufacturer recommends screwing no further than 3mm (1/8 inch) into the screw hole. | |

---- | ---- | ||

| Line 22: | Line 22: | ||

* Encoder Resolution: 64CPR | * Encoder Resolution: 64CPR | ||

| − | '''Metal | + | {|- |

| + | |[[File:CQGB37Y001-772.jpg |left|1200px]] | ||

| + | |} | ||

| + | ---- | ||

| + | {|- | ||

| + | |[[File:CQGB37Y001-773.jpg |left|1200px]] | ||

| + | |} | ||

| + | ---- | ||

| + | '''Motor Size''' | ||

| + | {|- | ||

| + | |[[File:CQGB37Y001-7751.jpg |left|1200px]] | ||

| + | |} | ||

| + | ---- | ||

| + | '''Metal Bracket Size''' | ||

| + | {|- | ||

| + | |[[File:CQGB37Y001-776.jpg |left|1200px]] | ||

| + | |} | ||

| + | ---- | ||

| + | '''Connect the Renderings''' | ||

{|- | {|- | ||

| − | |[[File: | + | |[[File:Motor5.jpg |left|600px]] |

| − | |||

|} | |} | ||

| − | + | ---- | |

'''Encoder Diagram''' | '''Encoder Diagram''' | ||

| − | Diagram for UNO | + | Diagram for Arduino UNO |

[[image:GLDJ-6.jpg|thumb|300px| center]] | [[image:GLDJ-6.jpg|thumb|300px| center]] | ||

| + | '''''Interrupt Port with Different Board''''' | ||

| − | + | '''''Notcie:''''' attachInterrupt() | |

| − | + | [[image:CQR-7.jpg|thumb|600px|center]] | |

| − | '''''Notcie:'''''attachInterrupt() | ||

| − | [[image:|thumb| | ||

For example,with arduino UNO board, you want to use interrupt port 0(int.0). You should connect digital pin 2 with the board. So, the | For example,with arduino UNO board, you want to use interrupt port 0(int.0). You should connect digital pin 2 with the board. So, the | ||

following code is only used in UNO and Mega2560. If you want to use arduino Leonardo or Romeo, you should change digital pin 3 | following code is only used in UNO and Mega2560. If you want to use arduino Leonardo or Romeo, you should change digital pin 3 | ||

instead of digital pin 2. | instead of digital pin 2. | ||

| − | |||

| − | + | '''See the link for detail''' http://arduino.cc/en/Reference/AttachInterrupt | |

| − | + | '''Encoder Sample Code''' | |

//The sample code for driving one way motor encoder | //The sample code for driving one way motor encoder | ||

| Line 96: | Line 111: | ||

else duration--; | else duration--; | ||

} | } | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 08:13, 17 October 2020

INTRODUCTION

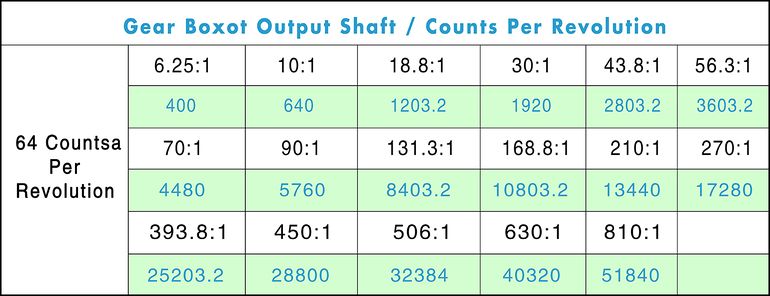

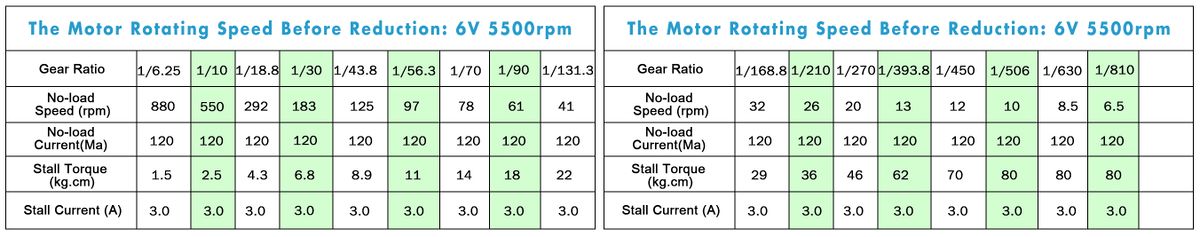

This gearmotor is a powerful 12V/6V brushed DC motor with a 6.25:1/10:1/18.8:1/30:1/43.8:1/56.3:1/70:1/90:1/131.3:1/168.8:1/210:1/270:1/393.8:1/450:1/506:1/630:1/810:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 5760 (90:1) counts per revolution of the gearboxot is output shaft. These units have a 16 mm-long, 6 mm-diameter D-shaped output shaft. When the working voltage of the DC gear motor is 12V, the motor rotation speed is 11,000 rpm before the motor is decelerated. When the working voltage of the DC gear motor is 6V, the motor rotation speed is 5500 rpm before the motor is decelerated.

Note

Stalling is likely to damage the gearmotor. Stall parameters come from a theoretical extrapolation of performance at loads far from stall. As the motor heats up, as happens as it approaches an actual stall, the stall torque and current decrease.

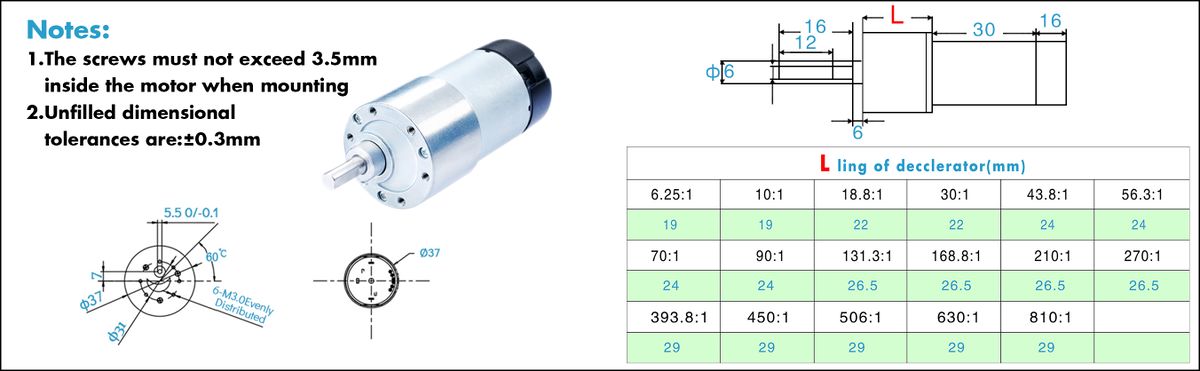

Do not screw too far into the mounting holes as the screws can hit the gears. CQRobot Manufacturer recommends screwing no further than 3mm (1/8 inch) into the screw hole.

SPECIFICATION

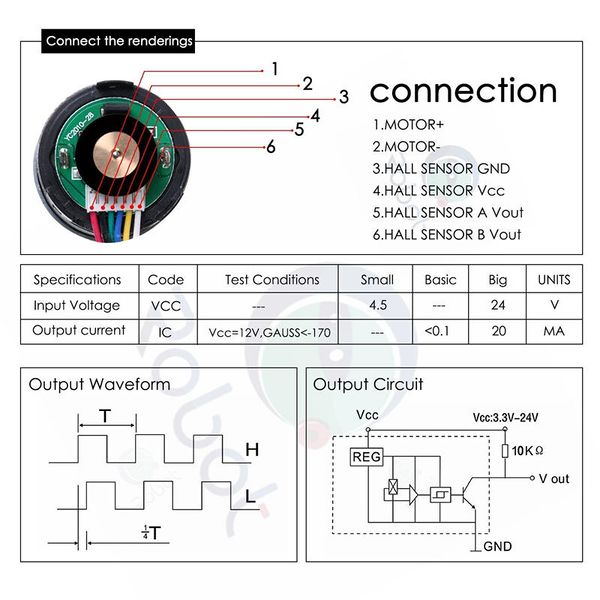

Motor Encoder

- Encoder Operating Voltage: 3.3V - 24V

- Encoder Type: Hall (Incremental Type)

- Encoder Resolution: 64CPR

Motor Size

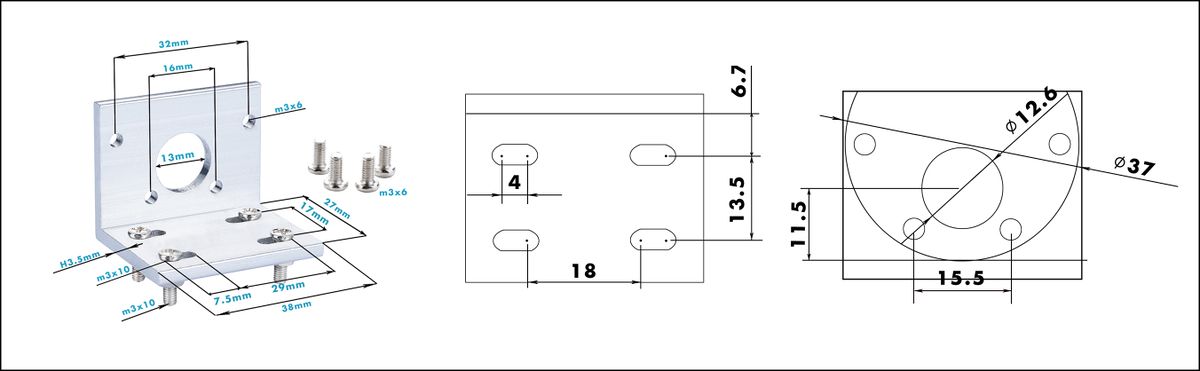

Metal Bracket Size

Connect the Renderings

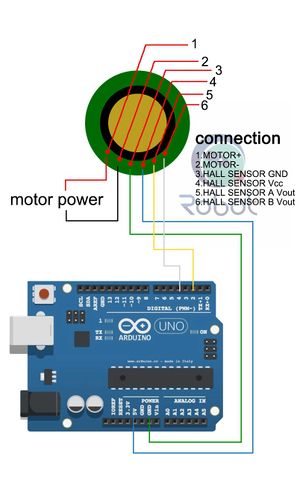

Encoder Diagram

Diagram for Arduino UNO

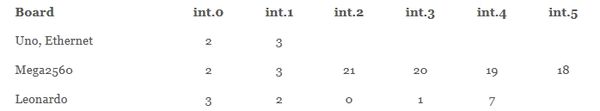

Interrupt Port with Different Board

Notcie: attachInterrupt()

For example,with arduino UNO board, you want to use interrupt port 0(int.0). You should connect digital pin 2 with the board. So, the following code is only used in UNO and Mega2560. If you want to use arduino Leonardo or Romeo, you should change digital pin 3 instead of digital pin 2.

See the link for detail http://arduino.cc/en/Reference/AttachInterrupt

Encoder Sample Code

//The sample code for driving one way motor encoder const byte encoder0pinA = 2;//A pin -> the interrupt pin 0 const byte encoder0pinB = 4;//B pin -> the digital pin 4 byte encoder0PinALast; int duration;//the number of the pulses boolean Direction;//the rotation direction

void setup()

{

Serial.begin(57600);//Initialize the serial port EncoderInit();//Initialize the module

}

void loop() {

Serial.print("Pulse:");

Serial.println(duration);

duration = 0;

delay(100);

}

void EncoderInit() {

Direction = true;//default -> Forward pinMode(encoder0pinB,INPUT); attachInterrupt(0, wheelSpeed, CHANGE);

}

void wheelSpeed() {

int Lstate = digitalRead(encoder0pinA);

if((encoder0PinALast == LOW) && Lstate==HIGH)

{

int val = digitalRead(encoder0pinB);

if(val == LOW && Direction)

{

Direction = false; //Reverse

}

else if(val == HIGH && !Direction)

{

Direction = true; //Forward

}

}

encoder0PinALast = Lstate;

if(!Direction) duration++;

else duration--;

}